Introduction of manifold and processing of kept CVD semiconductor:

Chemical Vapor Deposition is a very captivating process that has played a major role in industries that handle semiconductors. Just think about it: the creation of thin films of materials with precision unparalleled by any other method. It is here that CVD comes into prominence. As technology advances and high-performance demands for devices spiral upward, an understanding of every component in this intricate process becomes required.

The manifold is one such component, often the most overlooked but very essential in yielding the best results. It may seem simple, but keeping it hot makes all the difference in producing high-quality semiconductors. Why does temperature matter a lot? Let’s venture into the world of CVD and understand how maintaining a hot manifold enhances both performance and quality in semiconductor manufacturing.

Temperature-Importance in CVD Processes

Among the most influencing factors in CVD processes are temperature. The temperature factor directly influences reaction rates and material deposition efficiency. Ensuring exact temperature conditions provides proper vaporization of the reactants, leading to optimal film formation.

A temperature that is too low can lead to incomplete reactions, which can give rise to byproducts that are undesirable. On the other hand, too high temperatures can lead to rapid decomposition of precursors or substrate damages.

The ideal temperature range varies depending on materials used and the result one wishes to achieve. They will monitor this level carefully to ensure enhanced uniformity and quality in the film.

Precise temperature control further reduces defects in layers deposited on substrates. This is important in applications such as semiconductor fabrication, where performances depend on material integrity.

Without proper thermal management, the characteristics are difficult to achieve. Therefore, maintaining the appropriate temperatures is fundamental to successful CVD operations in various industries.

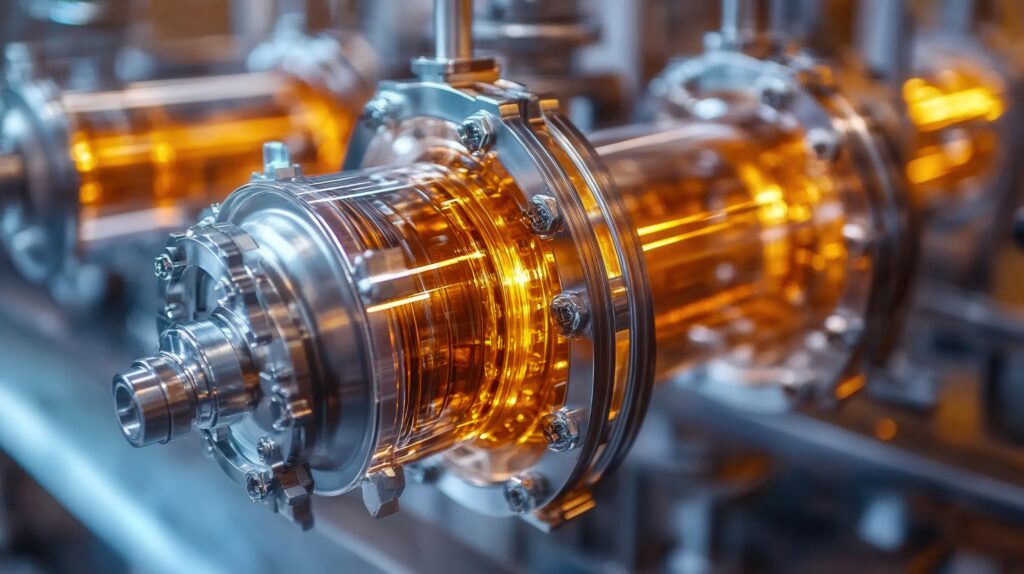

The Role of a Manifold in CVD Systems

The manifold plays an important role in CVD systems. It uniformly distributes precursor gases into the deposition chamber. This is quite important for uniformity purposes, in terms of film thickness and film quality.

Also, the manifold serves for gas flow rate and pressure control in the system. These parameters directly influence reaction kinetics in the CVD process. Under conditions of optimality, film formation becomes more accurate.

Another important role of the manifold is temperature stabilization. A manifold that is well regulated will prevent early condensation of the reactants so that only gaseous precursors enter the chamber. This greatly supports the improvement of general efficiency in semiconductor manufacturing.

In a word, without a manifold functioning well, coating of high quality would be hardly achieved; thus, the manifold is indispensable in CVD technology.

Keeping the Manifold Hot: Benefits

In CVD processes, manifold hot keeps the deposition quality high. High temperature eliminates the possibility of condensation for precursors; thus, the gases reach substrates while still in a vapor phase.

This consistent state prevents clogging and allows equal flow rates. A hot manifold also encourages optimal chemical reactions at high temperatures, hence improved quality and consistency in films.

Further, sustaining a warm environment within the manifold can reduce side-products during synthesis that would otherwise be produced in the case of compromised materials.

Good temperature control can pay great dividends in process stability. Operators enjoy fewer disruptions to production from maintenance or cleaning requirements when conditions are kept within their design envelope. This efficiency translates into higher throughput and lower operational costs over time.

In the end, a proper temperature handling would come out to deliver precision to layer thickness and composition, which is a major concern for any semiconductor application.

Common Problems in Manifold Temperature Control

In CVD processes, temperature control becomes very essential, and in fact, manifold temperature control presents an important problem. Such fluctuations can occur due to heating elements with inconsistencies and poor insulation problems. The latter may, in turn, cause deviations in deposition rates.

Other frequently encountered problems include temperature sensor calibration. If such devices are not well calibrated, operators get deluding data related to the real manifold temperature. In this case, it is not easy to maintain conditions at their optimal values required for chemical reactions.

In addition, residues can build up inside the manifold and reduce the effectiveness of heat transfer. The only way to avoid this problem from getting worse is regular maintenance.

Besides that, external conditions such as ambient temperature changes can make some modifications in manifold performance. Understanding and addressing these issues ensures better management of thermal conditions essential to successful CVD operations.

Hot Manifold Maintenance Best Practices for CVD Processes

In CVD processes, to keep the manifold hot continuously, continuous monitoring is required. Continuous measurement of temperature is done using precisely correct sensors. These sensors must be regularly calibrated to ensure accuracy.

Insulation is an essential determinant in heat retention. Thermal insulation materials that are good can considerably reduce the rate of heat loss and keep temperatures within the manifold at levels that are optimal.

Another important aspect is the proper maintenance of heaters. Check regularly for any wear and tear, or malfunctioning parts. This could prevent a sudden drop in temperature when upgrading aged equipment.

Similarly, the flow rates should be adjusted with consideration; too high or too low disrupts thermal stability. It is in balancing gas flows that one is able to efficiently heat while at the same time ensuring uniform deposition across substrates.

You can also read about: Geekzilla Autos Newest Developments

Consider routine cleaning protocols to get rid of any types of deposits that may develop either on or within the surfaces. A clean manifold has better heat transfer, therefore enhancing general efficiency in the system.

Summary-Consequences of Not Keeping the Manifold Hot in CVD Processes

A high manifold temperature in CVD processes is an important parameter to ensure consistency and efficiency in deposition. Heating the manifold prevents condensation of precursor gases, thus allowing their smooth flow into the reaction chamber. Such temperature control also encourages the uniformity of deposited thin films for better quality semiconductor devices. In summary, keeping the manifold hot involves not just optimization of reaction conditions but is highly associated with increasing the performance and precision of CVD processes in semiconductor manufacturing.

FAQs about this topic

When dealing with Chemical Vapor Deposition, questions do arise. Here is a set of frequently asked questions that may help explain your doubts.

What is CVD?

CVD is a process providing thin films and coatings on many substrates. Chemical reactions taking place between gaseous precursors result in solid deposits onto the treated surface. This technique finds applications mainly in electronics, optics, and materials science.

Why is the Manifold Kept Hot?

The manifold is the most important part of CVD processes, since it controls the flow of gases and keeps the process uniform. It is kept at a high temperature to avoid condensation of precursor gases inside the system and to provide proper reaction conditions toward the growth of films.

How does temperature influence the outcomes of CVDs?

The temperature strongly influences reaction rates and film properties in CVD processes. While higher temperatures could give a greater deposition rate, they might change material characteristics such as crystallinity or internal stress.

What are the drawbacks of a hot manifold?

Temperature cannot always be kept constant because of some equipment limitations or variations in the surrounding environment. Incorrect temperature readings result in a faulty pattern of deposition or film quality.

Are there specific tips in maintaining the manifold hot?

Regular temperature sensor calibration, proper insulation, and periodic heating element checks are some of the basic good practices that ensure proper manifold temperature management within the CVD process. This will help to enhance understanding of these aspects and, at the same time, enhance application efficiency wherever the use of CVD technology is applied.